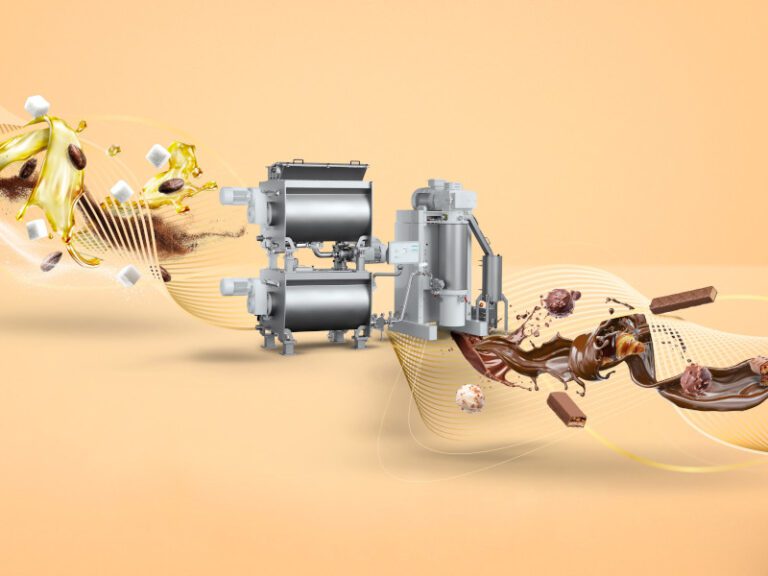

Syntegon’s integrated systems use intelligent automation, digital control, and confectionery expertise to help manufacturers achieve consistent, high-quality results

Producing gummies and jellies may seem simple from the outside – but confectionery manufacturers know it’s one of the most technically demanding product categories in the sweets industry. Small deviations in temperature, viscosity, or handling can make the difference between a perfect batch and costly waste. Syntegon addresses these challenges with integrated solutions that combine precise engineering, digital control, and decades of process know-how.

Inconsistent product quality and batch variations

Producers often struggle with batch-to-batch inconsistencies – differences in clarity, texture, or gloss that lead to increased material loss or rework. Syntegon tackles this with intelligent solutions, smart manufacturing through automation, analytics, and know-how. The Makat BC96 Oiling Drum, for instance, uses digital setpoints and monitoring to ensure consistent coating and shine across every production run, reducing variability to a minimum.

Rising recipe complexity and flexibility demands

Consumer expectations are shifting fast: vegan, low-sugar, seasonal, and functional gummies all require precise dosing and much more to enable rapid changeovers. Thanks to high depositing accuracy and tailless depositing technology, even highly viscous jelly masses can be handled with precision – ensuring a consistently high level of product quality.

Homogeneous mass and clarity

For perfectly transparent jellies, uniform homogenisation is key. Uneven heating or mixing can cause cloudiness or textural issues. The Makat BLK Rapidsolver ensures gentle, energy-efficient homogenisation, delivering consistently clear masses even with challenging recipes.

Smooth tray transport to reduce production-related mechanical failure

Once deposited, liquid gummy masses must be handled delicately to avoid deformation or surface damage. Conventional conveying systems often introduce shocks and vibrations. Syntegon’s Makat Roto-Step (RS) system uses servo-driven, chainless tray transport to minimise acceleration forces – protecting even the most intricate product designs.

Stable starch handling and environmental variability

Environmental factors like humidity and temperature can cause issues during starch conditioning, leading to defects or inconsistent drying. The Makat TF System precisely controls moisture, temperature, and airflow, ensuring stable starch quality and optimal demoulding performance – regardless of ambient conditions.

Surface finish and protection

A uniform, perfectly finished surface is vital for visual appeal and shelf-life. Uneven or excessive oiling for example can result in dull products or sticky surfaces. The Makat BC96 Oiling Drum provides automatic oil dosing, recipe-controlled parameters, and digital monitoring for reproducible results – every time.

Maintenance, downtime, and staffing challenges

With labour shortages and rising operational costs, manufacturers need systems that are intuitive, low-maintenance, and highly reliable. Syntegon designs its equipment with modular components, easy access, and reduced wear parts – helping to keep overall equipment effectiveness (OEE) high and downtime low.

Integrated process and faster time-to-market

Many producers rely on multiple suppliers for different process stages – often resulting in complex integration work and extended commissioning times. Syntegon’s gummy turnkey lines combine cooking, depositing, starch conditioning, oiling, and even packaging into one seamlessly integrated system. The result: faster start-ups, fewer interfaces, and shorter development cycles.

From kitchen to packaging, Syntegon provides confectionery manufacturers with end-to-end solutions that enhance quality, increase flexibility, and reduce waste. By combining intelligent automation with process expertise, Syntegon empowers producers to achieve one goal above all: the perfect gummy, every time.

Find more at: https://www.syntegon.com/solutions/food/confectionery-packaging

Read more latest industry news and developments in our free to download magazine.

Never miss a story… Follow us on:

LinkedIn: International Confectionery

YouTube: @ConfectioneryTV

Media contact

Joseph Clarke

Editor, International Confectionery

Tel: +44 (0) 1622 823 920

Email: editor@in-confectionery.com