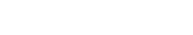

Tanis CCO Wouter Tanis shares how smarter systems, precision controls and modular equipment are enabling confectionery manufacturers to innovate at scale…

What are the most exciting trends in confectionery production technology right now?

At Tanis, we are closely following developments in the confectionery industry and supporting manufacturers as they adapt to new challenges. From automation improvements to cleaner and more sustainable recipes, production processes are evolving to be more efficient and flexible.

Modern production lines must deliver more than output; they need consistency, adaptability, and scalability. Tanis machinery supports a wide range of production needs, from lower capacity and private label production to fully automated high capacity manufacturing. Fast changeovers and precise process control help manufacturers respond to market demand without compromising quality.

Consumer preferences are shifting toward products that are healthier and more sustainable. Tanis equipment is compatible with natural ingredients and reduced-sugar formulations, supporting fruit-based treats, functional candy, plant-based alternatives, among others. Sustainable production practices are also addressed, including the use of conical vessels, starch conditioning in specialised rooms, and energy reuse within production processes.

Gummies remain a widely consumed product with opportunities for innovation, including technologies like 3D moulding and center-in-shell depositing. Beyond gums and jellies, Tanis provides solutions for chewy candy, bars, fondants, hard candy and caramels. This enables manufacturers to expand product portfolios while working with a trusted partner for support, knowledge, and service. Our Tanis Innovation Center allows ideas to be tested, refined, and scaled, with experts collaborating alongside clients to explore new recipes, optimise processes, and identify market opportunities.

Regional trends vary: APAC and EMEA show growth in gums and jellies, while the nutraceutical segment offers potential despite regulatory and economic challenges. In mature markets like the US, replacement investments and lower MOQs are a focus. Functional ingredients such as adaptogens and protein infusions are increasingly relevant, and AI tools are being used to support faster, consumer-focused product development. Precision automation, once limited to specific production steps, is now affecting standards across entire confectionery lines.

What are the biggest hurdles manufacturers face in scaling up from small batch to industrial production while keeping product quality consistent?

Scaling up from small-batch to industrial production while maintaining product quality presents several key challenges. First, manufacturers must ensure process consistency across larger equipment, where variables like temperature, pressure, and mixing speed can behave differently. Second, recipe control becomes more complex; small deviations can lead to noticeable changes in texture or flavour. Third, infrastructure demands grow significantly, requiring additional space, staff, and investment. Fourth, automation integration must balance efficiency with flexibility, especially for seasonal or niche products. Finally, organisational readiness, from training to cross-team coordination, is essential to avoid bottlenecks and maintain quality at scale. To guide candy producers through this process, we provide tailored training and education through the Tanis Academy. And of course, to gain a firm grip on processes and recipes, our Tanis Innovation Center is available to support our global partners.

How is processing technology adapting to handle reduced-sugar, plant-based and clean-label ingredient formulations?

Tanis is adapting its processing technology to meet the rising demand for reduced-sugar, plant-based, and clean-label formulations, with a focus on flexibility and precision. Our systems accommodate alternative sweeteners, such as maltitol and fruit-based options, which require careful control of cooking and mixing to preserve texture and flavour. For plant-based ingredients, Tanis equipment is designed to handle variations in protein and fiber content, ensuring consistent results across different formulations. Clean-label production is supported through minimal processing, automated controls, and customisable line configurations; helping manufacturers meet consumer expectations without compromising quality. All of this comes with the support of Tanis experts from diverse fields of expertise, ensuring guidance and know-how at every step.

How do you see digitalisation and process control shaping the future of confectionery production lines?

Digitalisation and process control are increasingly shaping confectionery production, improving precision, efficiency, and adaptability. Tanis is supporting this evolution through scalable, recipe-driven systems such as the 800 Robotic High-Capacity line, which uses servo-driven automation to increase output without raising machine speed.

In the near future, AI-enabled smart factories will provide real-time analytics, predictive maintenance and automated inspection systems that help reduce defects and optimise output. These technologies will allow manufacturers to adjust ingredient ratios, monitor quality and minimise waste, while addressing growing consumer demands for consistency and sustainability. As digital tools continue to develop, they are becoming an integral part of innovation and competitiveness in confectionery production.

What processing considerations are most critical in achieving the right structure and mouthfeel across different product categories?

Achieving optimal structure and mouthfeel in confectionery products relies on precise control of processing parameters. Factors such as temperature, mixing speed, and cooling rates directly influence crystallisation, aeration, and emulsification, which are essential to texture formation. The functional properties of ingredients, such as sugar types, hydrocolloids and fats, must be selected and adjusted to match the intended sensory characteristics of each product. For instance, fondant requires carefully managed crystallisation for smoothness, while gummies depend on accurate moulding and conditioning cycles. Flexible equipment and real-time monitoring support consistency from batch to batch. At Tanis, aligning process design with ingredient behaviour helps ensure products meet defined standards for texture, mouthfeel, and overall quality. Of course, relying on the knowledge of our dedicated food technologists and process engineers.

Read the full interview in our free to download latest issue here