Prioritising energy efficiency, sustainability, and high-performance solutions, the CHOCOTECH provides turnkey systems that optimise every stage of confectionery manufacturing

The variety of confectionery bars is endless – bars in all shapes and sizes, whether cereal bars, candy bars, fruit bars or, of course protein bars, enjoy constant popularity. As a subsidiary of SOLLICH KG, CHOCOTECH GmbH is aware of the requirements of its customers and develops systems for the efficient, energy-saving and hygienic production of these products.

When it comes to new production systems in the confectionery industry, energy saving is one of the most important factors today, alongside system efficiency, CIP capability and availability. This calls for science and innovation – and the CHOCOTECH team has taken up this challenge from the very beginning. According to the motto “keep it simple, but effective”, the experts from Wernigerode offer the best solutions – from raw material handling to the finished product – as a “turnkey solution”.

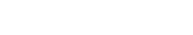

Bar production

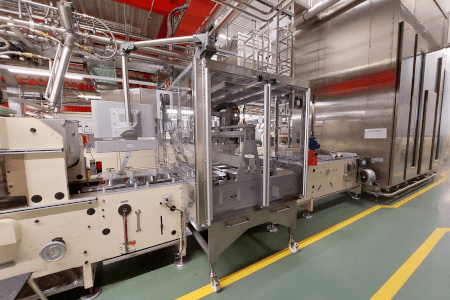

There are different processes for producing the various bar masses, depending on the system throughput to be achieved and the product. Production in batches with the CARASTAR® as well as continuous production with SUCROFILM®, SUCROTWIST® and CARAFLEX® enable maximum efficiency and product quality. Production success depends on various factors. Precise PLC-controlled monitoring of the process and system parameters, such as weighing, mixing, cooking temperature and flow rates, is essential for sustainable product quality.

Precise control of the cooking temperature, dwell time and, if necessary, aeration also plays a key role in the production of bar masses such as caramel, mousse nougat, sugar binder masses, fruit masses, etc. and has a direct influence on product quality. Turnkey solutions with systems from SOLLICH KG and from CHOCO-TECH as a member of the SOLLICH group of companies, equipped with the world’s best-selling and most successful bar forming system CONBAR® for over 40 years, set standards in the efficient and high-performance production of bars.

CHOCOTECH – over 104 years of expertise

CHOCOTECH GmbH can look back on over 104 years of experience as a successful system supplier of process and production systems for the confectionery industry. Part of SOLLICH KG since 1992, with headquarters in Wernigerode and representatives all over the world, the experienced candy experts offer solutions for confectionery such as jellies, chewy candies, hard candies, caramel, fondant, aerated candy masses, laminated candies, Halwa and OTC soft and hard candies.

Sustainable from consulting to production

The experts from Wernigerode focus on preparing for future production requirements, conducting forward-looking research and developing adaptable systems. As a result, CHOCOTECH GmbH not only offers CIP-capable systems and places particular emphasis on efficiency and resource-saving production but also works closely with its customers to optimise existing systems and adapt its coaching sessions to individual needs.

Read more latest industry news and developments in our free to download magazine.

Never miss a story… Follow us on:

LinkedIn: International Confectionery

YouTube: @ConfectioneryTV

Media contact

Joseph Clarke

Editor, International Confectionery

Tel: +44 (0) 1622 823 920

Email: editor@in-confectionery.com