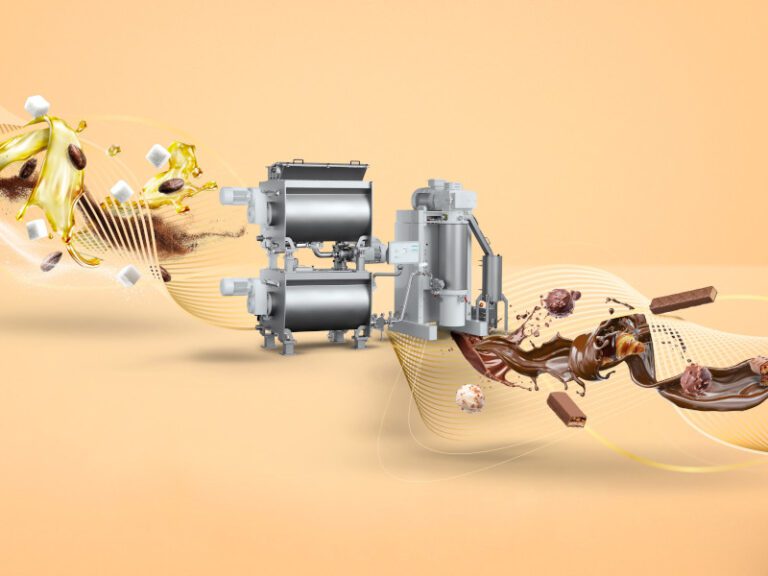

ILLEXAO™ EN 10 from AAK optimises enrobing performance, cutting buildup and downtime while preserving texture, gloss, and efficiency

Soaring cocoa butter prices since 2024 have driven chocolate manufacturers worldwide to increase their use of cocoa butter equivalents in recipes. While this shift supports cost-efficiency, affordability, and sustainability, it also introduced significant technical challenges in enrobing operations. Manufacturers experienced faster buildup of solidified chocolate in enrober machines, leading to downtime, reduced throughput, and potential quality issues. Addressing these challenges without compromising product performance became a key industry need.

AAK has responded with ILLEXAO™ EN 10, a cocoa butter equivalent for enrobing with super compound. Its proprietary formulation replicates critical physical properties of cocoa butter while enhancing thermal stability and flow behavior. By carefully balancing fat composition, ILLEXAO™ EN 10 reduces buildup, minimises downtime, and maintains machine capacity, enabling manufacturers to scale alternative usage without compromising texture, gloss, or mouthfeel.

Development of ILLEXAO™ EN 10 combined rigorous research with advanced testing. Internally, AAK employed RheoSmart to measure viscosity and solidification rates under realistic processing conditions. Efficient pilot trials simulated industrial enrobing, allowing scientists to optimise the formulation for consistent flow, thermal behavior, and stability. Iterative testing, coupled with early adopter feedback, ensured ILLEXAO™ EN 10 would deliver both operational efficiency and the indulgent experience consumers expect.

Impact metrics confirm the solution’s effectiveness. Manufacturers experienced measurable reductions in downtime and smoother production schedules, while quality parameters such as coating uniformity and texture were maintained. Internal analyses also indicated potential energy savings and reduced waste during remelting cycles. These benefits underscore ILLEXAO™ EN 10’s ability to turn market pressures into opportunities for operational improvement and sustainability.

The project also exemplifies AAK’s internal culture of collaboration and innovation. Cross-functional teams, including research scientists, application professionals, and marketing and commercial specialists, worked closely to translating market challenges into actionable solutions. Insights gained from RheoSmart testing and pilot trials inform future innovations, strengthening AAK’s capacity to anticipate and respond to evolving industry needs.

By enabling manufacturers to adopt cocoa butter alternatives without operational compromise, ILLEXAO™ EN 10 addresses immediate production challenges while supporting broader trends in sustainability and cost efficiency. It demonstrates AAK’s commitment to delivering high-performance, reliable, and consumer-focused solutions that create lasting value for both manufacturers and end consumers.

Read more latest industry news and developments in our free to download magazine.

Never miss a story… Follow us on:

LinkedIn: International Confectionery

YouTube: @ConfectioneryTV

Media contact

Joseph Clarke

Editor, International Confectionery

Tel: +44 (0) 1622 823 920

Email: editor@in-confectionery.com