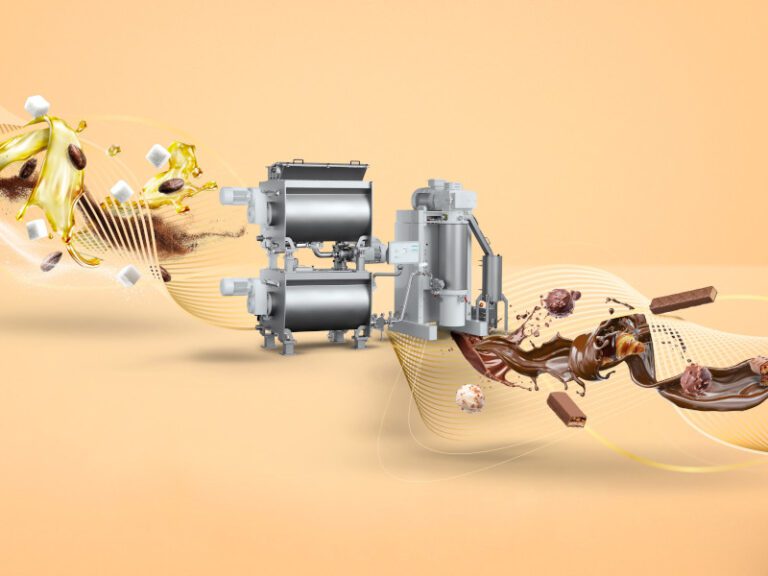

Swiss chocolate producer Maestrani Schweizer Schokoladen AG and Swiss technology group Bühler are taking their long-standing partnership to the next level through digitalisation. With the support of Bühler’s advanced digital solutions, Maestrani has achieved an 18% increase in production efficiency, while gaining transparency and laying the foundation for a smart factory.

With a heritage spanning more than 170 years, Maestrani produces over 4,500 tonnes of chocolate annually for its iconic brands Minor, Munz, and Maestrani. At its Flawil site, the company also welcomes over 230,000 visitors each year to its immersive Chocolarium World of Discovery.

Guided by its purpose of “making the world sustainably happier, bit by bit,” Maestrani is committed to continuous improvement and innovation. “To meet growing consumer expectations and ensure our long-term competitiveness, we must be faster, more adaptable, and ready for future challenges. Digitalisation plays a key role in achieving this,” says Christoph Birchler, CEO of Maestrani.

Embracing data transparency with Bühler Insights

In 2016, Maestrani initiated its digital transformation journey in collaboration with Bühler, aiming to enhance process transparency and efficiency. Central to this effort is Bühler Insights, Bühler’s digital platform that connects machines, aggregates data, and visualises operational performance.

By installing intelligent sensors across critical equipment, Maestrani began capturing real-time data from various production steps, including mixing, refining and conching. Bühler Insights consolidates this information, enabling operators and managers to monitor key performance indicators (KPIs), identify inefficiencies, and make data-based decisions.

“With Bühler Insights, we now collect and analyse dozens of data points per machine. This level of transparency allows us to move from reactive to proactive process management,” says Patrik Keller, Head of Production & Logistics at Maestrani.

Based on the data in Bühler Insights platform, the Bühler and Maestrani experts together built a virtual model to simulate possible process improvements before implementation. This virtual simulation minimises disruptions and accelerates continuous improvement initiatives.

“Our approach combines real-time monitoring with advanced analytics to optimise overall equipment effectiveness (OEE), improve resource efficiency, and support continuous improvement,” says Fabian Dintheer, Digital Program Manager at Bühler.

Turning insights into action

A key outcome of this collaboration was the identification of a bottleneck in the five-roll mill refiner. Using Bühler Insights, Maestrani quantified the inefficiency and simulated improvement scenarios. One targeted intervention involved installing a new conveyor system to streamline material flow, resulting in a remarkable 18% increase in efficiency in chocolate mass production.

“With data transparency, we transitioned from relying solely on experience to making data-based decisions. This was a game-changer for our operational efficiency,” says Patrik Keller, Head of Production & Logistics at Maestrani.

A partnership driving innovation

Maestrani and Bühler have been working together since 1985, evolving from a traditional supplier relationship into a strategic partnership. Bühler leverages Maestrani as a pilot site to test and refine its digital innovations in real-world conditions.

“Maestrani has been an ideal partner for us because of their openness to innovation and their willingness to explore new ways of improving production. By working together in real production environments, we have been able to refine our digital solutions and unlock significant efficiency gains. This partnership demonstrates how data transparency and collaboration can drive tangible results – not only for productivity but also for sustainability and quality,” says Fabian Dintheer, Digital Program Manager at Bühler.

Towards a smart chocolate factory

Building on this success, Maestrani is pursuing a broader smart factory vision. Future steps will focus on expanding traceability, optimising conching processes, and further automating production with minimal manual intervention. These initiatives will help Maestrani meet market demands, address workforce challenges, and produce more sustainably.

“Digitalisation is not just about increasing output. It is about producing smarter, with better quality, less waste, and more agility. This is essential for our future success,” says Birchler.

Read more latest industry news and developments in our free to download magazine.

Never miss a story… Follow us on:

LinkedIn: International Confectionery

YouTube: @ConfectioneryTV

Media contact

Joseph Clarke

Editor, International Confectionery

Tel: +44 (0) 1622 823 920

Email: editor@in-confectionery.com