How have robotics, namely Pick and Place robots, changed the landscape of the confectionery packaging sector for the better?

As Bill Gates once said, “Robotics and other combinations will make the world pretty fantastic.” Unsurprisingly, there is a pretty high expectation with regards to how robots will benefit humanity, with the hope that these crafty inventions will enter into any public sphere possible. For the past couple of years, robotics have been slowly transpiring into various confectionery sectors with the supposed aspiration to have these automated machines dominate the industry completely. One sector in the confectionery industry that is heavily reliant on robotics and automation is the packaging sector. Following this, this exclusive feature will assess how robotics are revolutionising the packaging sector and further robotic innovations that will shake up the industry.

Overseeing confectionery robots

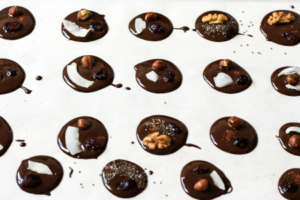

There are a vast array of confectionery robots on the market that hold varying purposes. There are robots available that manage the moulding of a given chocolate product or automotive systems that ensure that the cooking processes are at optimum levels. A recent example of this is Kuka’s launch of the chocolate-praline making robot that was first situated at the Zotter factory in Austria. The robot known as the KR Agilus is capable of turning chocolate into bars or pralines, as well as handling the temperature of delicate confectionery products. The robot’s grip and rhythmic movements ensure the robot’s capability to pour liquid into moulds and swings the mould to ensure even distribution.

Other confectionery robots also allow decorating and structuring of a confectionery product such as decorating robots that ensure that a particular baking or confectionery product, such as cake, gets the most accurate and intricate designs displayed on the product. Also, the incorporation of 3D printing chocolate has also opened up avenues as to how chocolate is formed and made. As the craft of confectionery decorating is going out of fashion, robots are able to pick up the pieces and ensure that confectionery companies still create an aesthetically pleasing product.

It is fair to say though that packaging robots are a considerably sought-after item. The most common form of packaging robots are called pick and place robots. These robots are commonly used in modern manufacturing environments. They work by firstly being mounted on a stable stand which allows the machine to reach and access the entire belt or production line. They pick up a product via suction cups that are attached to the robotic arm and move it to the desired location. Advanced vision systems enable them to grasp and move objects in a conveyor belt, which can be then used in a variety of different ways. Pick and place innovations have been occurring with regards to speed, precision, versatility and efficiency. Companies such as Schubert, ABB and Smart Robotics are looking for ways to further innovate their products, so let’s assess the various ways that packaging systems and pick and place robots are becoming more advanced to meet consumer and company demands.

Read more of this article in our latest edition here: March 2022 Single Issue form – International Confectionery Magazine (in-confectionery.com)

Media contact

Roshini Bains,

Editor, International Confectionery

Tel: +44 (0) 1622 823 922

Email: editor@in-confectionery.com