Stefania Montalti, Communication Manager at CEPI explains the process to create invert sugar and how its properties offer better flavour and texture for the confectionery and baked goods sector.

A family-run company with an international outlook, CEPI designs and manufactures turn-key systems for the storage, conveying and metering of raw materials, as well as fully integrated automation and technologies to complete all production processes. They were established in 1985 and are based in the Emilia Romagna region in Italy.

CEPI prioritises flexibility, research, and the ability to provide a specialised product to each customer. They build around 300 custom installations every year, focusing on the specificity and diversity of each installation and developing technologies according to their needs. This approach results in constant research and innovation leading to unparalleled technological range. Similarly, every project is built around the development of close relationships with the customer through an ongoing conversation that involves all aspects of the project from analysis, to engineering and control, manufacture, installation and service.

What is invert sugar?

Invert sugar is a liquid sugar made from splitting sucrose into glucose and fructose through hydrolysis, a process in which it is mixed with water and heated with a catalyst until the bonds between glucose and fructose break. It is chemically and physically different from granulated sugar (the common name of sucrose): thick, liquid and hуgrоѕсоріс, it easily аbѕоrbs mоіѕturе and extends the shelf life of the products in which it is used. Because fructose is the sweetest natural sugar, the sweetening power of invert sugar is much higher than that of table sugar.

Early sugar chemist Augustin-Pierre Dubrunfaut was the first to explore the possibilities in sugar inversion – in the beginning of the 19th century, he speculated that sucrose could be made into a mixture of glucose and fructose in equal ratios through heating with acid. In 1836, Biot observed the rotation of polarised light that gives invert sugar its name: invert sugar reflects light in the opposite direction of sucrose – sucrose solutions rotate polarised light to the right while invert sugar rotates it to the left.

Today, invert sugar is used extensively across wide range of food industries: from baked products for its freshness-preserving properties and the better crust colour they provide, to confectionery preparations where it adds moisture and depresses the freezing point, adding softness, to syrups in the pharmaceutical industry, where it improves mouth feel. Because of its humectancy, invert sugar even found its way in the paper and tobacco industries.

Most of the sugar in honey is invert sugar, which bees naturally produce while transforming nectar into honey. It makes invert sugar preferable for bee feeding: if fed wіth rеgulаr ѕugаr, bees will first turn it intо invert sugar before they can аѕѕіmіlаtе іt. Bees break down sucrose with an enzyme called invertase, secreted by their glands. Invertase, which can be also derived from yeast, is used in industrial production of invert sugar as the catalyst during enzymatic hydrolysis.

Invert sugar is automatically present in jams, as the process makes sugar interact with the acid in the fruit and heating. Professional chefs use it for its flavour and texture enhancing properties: in pastries such as ganaches, the use of invert sugar adds much better smoothness and mouth feel.

Further benefits and applications

Invert sugar is mostly known for its sweetening power and freshness preserving properties, but its benefits are extensive.

Its sweetness is around 20-25% higher than that of sucrose, making it a very cost-effective choice as less product is necessary, allowing for significantly reduced consumptions and resources saving. The extra sweetness makes invert sugar very popular in confectionery productions such as candies, cakes and ice cream, baked goods such as pastries and cookies, soft drinks and energy drinks. Its freshness-preserving properties have led to broad application across food sectors: from confectionery to baked goods to fruit processing, only to name a few.

Invert sugar lowers the freezing point and delays crystallisation. As such, it improves the upright power of creams and makes ice cream and fillings creamier. It is very useful for icings and glazes and provides a consistent, soft centre to candies and chocolates. With its higher affinity for water, it can be used as humectant in cakes and similar products, and it enhances colour and flavour as well as freshness. It makes baking faster as well as adding softness to baked goods.

With less crystallisation, invert sugar creates a smoother texture and improved mouth feel. Due to the presence of free fructose and its natural affinity for fruit flavours, it is used for soft drinks as well as confectionery or bakery goods that contain fruit or are fruit flavoured. Invert sugar gives a richer crust colour to bread and pastries as it boosts the Maillard reaction, the chemical reaction between amino acids and sugars that adds distinctive colouring and flavour to browned food.

It is ideal for use in energy drinks and sports drinks, because fructose is more satiating and because of the added taste from glucose and fructose.

Invert sugar is used in the production of biscuits for better flavour and texture. During production, it significantly contributes to the reduction of capillary breakage. In the production of baked biscuits it releases less residues on the mould than sucrose, with an improvement in line management. Its high solubility makes it vastly easier to amalgamate in the dough during production.

Invert sugar is also commonly found in cereal goods, granola bars, yoghurt, infant foods and syrups in the pharmaceutical industry.

The process and CEPI’s technology

Inversion splits disaccharides into its component monosaccharides. In the case of sucrose, the bonds between the chemical glucose and fructose molecules by a process called hydrolysis, which is the chemical breakdown of a compound due to reaction with water. The sucrose solution is subjected to heat and a catalyst, which can be enzymes such as invertase or an acid ingredient like citric acid. The acidity can be then reduced or neutralised with alkaline substances such as baking soda.

As well as the type of catalyst, the amount of water and sugar and the temperature of the heating process can be adjusted: more water will lead to longer conversion times and more inversion, and higher temperatures generally lead to a thicker product.

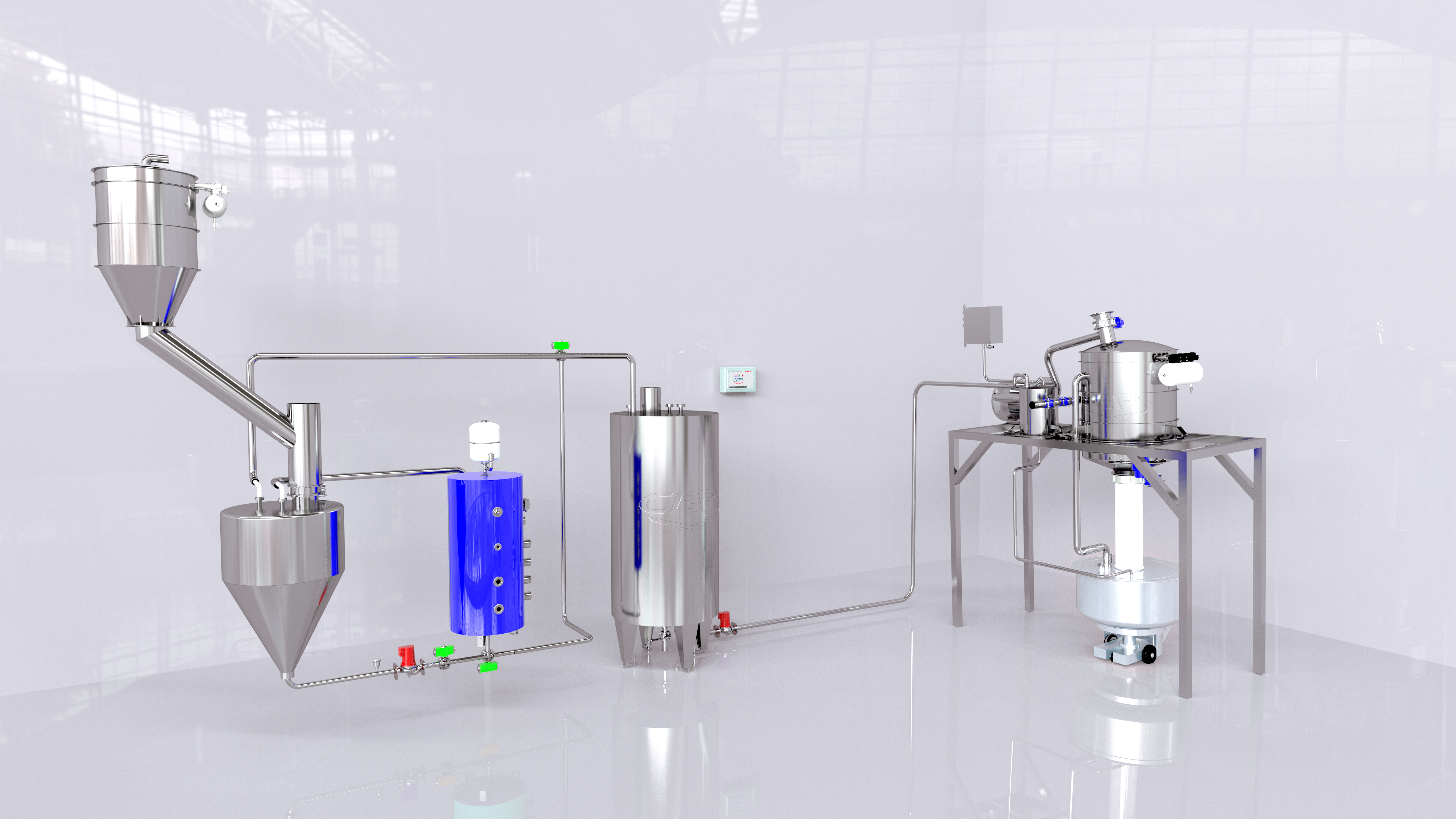

In-house production of invert sugar sharply increases flexibility, as it allows for complete control over process and parameters as well as removing the need for storage. Food manufacturers who decide to go this route need a system that is rational, versatile and fully customised. The CEPI system handles the preparation, storage and metering of invert sugar and can be fully or partially automatic depending on customer’s needs. As all of CEPI’s technologies, it is highly versatile, allowing for both acid and enzymatic hydrolysis and complete control of parameters such as amount of water and temperature.

The system comes with a hopper for crystal sugar, heating device, production tank and exchanger with continuous recirculation, and storing tank. Invert sugar can be cooled before storing or after through an exchanger and chiller. The system includes temperature check with sensors and weighing cells, and allows for both manual or automatic feeding from the line and dosage of catalyst.

CEPI’s solution ensures shortened heating times and highly efficient mixing, delivering a homogenous blend in a very short time, and the system optimises steam, reducing waste and costs as well as production times. It standardises and rationalises production as well as improving the quality of the final product. With vast food technology expertise, CEPI is also able to provide support during the creation of a recipe, to find the perfect combination of process and ingredients to match the final product.