Michael Haas, Global Product Manager for secondary packaging at Syntegon outlines the benefits to automation in packaging and advancements in using robotics

Automation in packaging has been a big trend for some time. This has only been accelerated due to the global pandemic, which put heightened focus on hygiene, staffing production and the food packaging process as a whole. Syntegon Technology, formerly known as Bosch Packaging Technology until late 2019, presented itself as an independent enterprise at the company headquarters in Waiblingen (Germany). It has since worked to establish itself with a business focus on intelligent and sustainable technologies for the pharmaceutical and food industries. In January this year, Syntegon launched the new Sigpack TTMD – a top load cartoner with seamlessly integrated delta robots. They are also due to launch a completely new robotic platform with modular cells for pick and place applications. International Confectionery’s Editor, Kiran Grewal, sits down with Michael Haas, Global Product Manager for secondary packaging at Syntegon, to better understand the developments being made at the company and why automation and technology is driving packaging to new heights.

So, why is automation in packaging necessary? Haas says automation reduces repetitive manual tasks and makes the operation more efficient by allowing manual power where it’s really needed and necessary. “Manual work is often used for repetitive tasks like loading cartons by hand. The benefit you get from automation is that you can reduce manual processes and use these operators for other tasks within your production, which can’t and should not be automated,” he explains.

“As humans we make mistakes, especially if the work is highly repetitive. If you are doing the same work, like placing products into a box, for eight hours a day, it is likely that concentration will slip, and elements will get missed. Then, your product quality and waste levels will take a hit. In addition, you have to take into account the speeds of which these machines operate, too. At a certain speed, it means it is not possible to do the job manually anymore. By using automation, your packaging process is stable and runs efficiently. You can plan better and improve your overall production performance and you have control over stopping the machine when you need to clean or changeover to a new format.”

“By using automation, your packaging process is stable and runs efficiently”

Automation in packaging became prevalent during the pandemic, and Haas says Syntegon was best placed to offer these solutions due to its broad product range, meaning it was able to offer suitable, best fitting solutions for companies who have smaller production volumes but also for larger companies or even global corporations who produce very high volumes.

“These small companies may need a lower level of automation at the beginning. However, if their products become successful in the market and demand is increasing, they need to expand their production capacity to make sure that they can deliver. In that case, a certain level of automation is required to reach the desired output.”

“Out of our portfolio we can offer automation solutions for single process steps all the way up to fully automated packaging lines. A customer may start with a single former to erect cartons. In the next stage, they may add a carton closer and/or a product loader. We have solutions for every step of the packaging process. At some point, the investment into a fully integrated cartoning unit where all these functions are integrated into one machine makes sense. It reduces complexity and increases efficiency.” Haas says.

“Out of our portfolio we can offer automation solutions for single process steps all the way up to fully automated packaging lines. A customer may start with a single former to erect cartons. In the next stage, they may add a carton closer and/or a product loader. We have solutions for every step of the packaging process. At some point, the investment into a fully integrated cartoning unit where all these functions are integrated into one machine makes sense. It reduces complexity and increases efficiency.” Haas says.

Delta robots – how do they work?

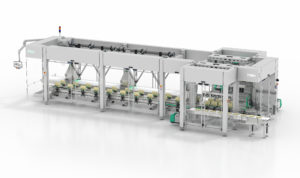

Syntegon recently launched the Sigpack TTMD, which is their new top load cartoner, and the D stands for delta robotics for the loading. The new machine builds on the Sigpack TTM, which is their proven integrated top load cartoning platform.

Haas comments: “Within the TTM platform we always fully integrate carton forming, loading and closing. We also use linear axis or three axis robots for product loading. This works, for example, very well for products from the chocolate industry such as bars.

“Other products, like crisps or smaller confectionery products are typically coming out of vertical baggers. They are usually not that nicely aligned on the infeed belt and you have to handle these products as singles. They come with varying pitches and orientation. It works best to pick them with a single pick and place them into a cardboard box. In this case delta robotics technology is very well suited. In combination with a camera based vision system, the robots reliably pick these random products from the belt and place them either flat or on-edge into the box. Our delta robots have – depending on the product – a cycle rate of up to 120 picks per minute,” he explains.

“In combination with a camera based vision system, the robots reliably pick these random products from the belt and place them either flat or on-edge into the box”

For the TTM platform, Syntegon now has the capability to use fully integrated delta robots inside the TTM machine for loading of products into a box, and with this, using this adaptability for single pick and place you get more flexibility with the kind of products and pack styles that you can handle.

Haas adds: “As you will see with the launch of our new delta robotics platform, the Syntegon RPP, we also handle unpacked products such as naked cookies or chocolates for example. In this case, the end effectors of the delta robots play an important role. This requires know-how. We have a lot of experience in what tools are needed to handle different kinds of products. Is it fragile, does it have a crumbly surface, is it large, is it small? Besides the handling part, easy and fast format changes are always taking a top priority. We have a really easy and repeatable change over philosophy with our machines. Format and/or product changes can be easily done by any operator.”

Haas says that because these changes are so easy, it wouldn’t require an engineer to administer it, rather it can simply be done with pre-set format parts or with click tools, so an operator would have no problem in doing this. “What is always important is not just that the format change is simple, but that it is also reliable and repeatable. After a format change you press the start button and the machine is running. You don’t need any fine tuning. All Sigpack TTM machines produce 100% quality right from the first carton, and onwards.”

Sustainability in packaging

Syntegon notes that besides automation another top trend in packaging is sustainability.

“I think sustainability is very important for the packaging industry. If we talk about primary packaging for example, we see a strong desire to switch from multi-layer plastic material to for example paper-based material. The handling of paper is very demanding. We offer solutions where manufacturers can retrofit their existing machine to be able to run paper-based material without compromising on speed.”

“Primary packaging in paper also impacts secondary packaging. Now, you have a product, which is wrapped in paper. This is different compared to plastic films. You must be careful to keep the delicate barrier layer intact when you place the products into the carton. So gentle handling in secondary packaging is key – a factor which is often overlooked when switching to paper. This also requires know-how, experience and refined gentle feeding solutions,” Haas says.

“we will take a stronger focus on flexibility and how we can utilise the new technologies available, such as linear electromagnetic motor drives”

Future trends in packaging

Haas predicts: “I think further progress on sustainability developments will be key. In addition, we will take a stronger focus on flexibility and how we can utilise the new technologies available, such as linear electromagnetic motor drives. I also think that automation in general will grow and robotics, especially delta robots, will play a big role in this respect.

“Last but not least, digital solutions are on the rise. Remote service for example was key during the pandemic when travelling was not possible. Using data analytics to increase efficiency of the line in different ways, making smarter planning of maintenance cycles are just a few examples.

“At Syntegon, we always observe the market and analyse trends. We are known as innovators and it is our goal to make the job easier for our customers.”

To stay up to date on the latest, trends, innovations, people news and company updates within the global confectionery market please register to receive our newsletter here

Media contact

Kiran Grewal

Editor, International Confectionery

Tel: +44 (0) 1622 823 922

Email: [email protected]