Extrufood celebrate their new successful innovations and developments in the confectionery machinery market and outline what they will present at ProSweets 2022.

Extrufood has established themselves as an extrusion expert in the confectionery industry and announces for 2022 a promising strong year with new developments of their machinery and upcoming expansion projects. They are set to attend the ProSweets (Hall 10.1 stand C059) for the first time to exhibit their well proven most popular products for the confectionery industry.

During and after the covid pandemic, the current global commercial demand in the confectionery market has taken a huge leap and Extrufood has had a very active year in 2021 and the next year looks just as promising. The demand for comfort food is increasing massively and it is showing in the confectionery market.

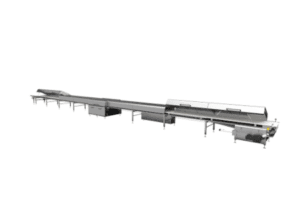

Extrufood offers an exciting variety of new and upgraded versions of the existing equipment for the optimisation of the customer’s production process. With its expertise and great experience, Extrufood supplies custom made production lines from 20 kg/hr to up to 2.000 kg/hr, which ensures almost limitless possibilities of confectionery products. The production lines create an exciting variety with up to eight different colours and flavours, with various fillings and coatings.

Extrufood is happy to announce they have developed a new machine which they can add to their customised elements: a Z-blade discharge mixer with a capacity of at least 300 kgs per batch, which is ideal for the mixing and kneading of sugar paste and other masses, to be used for sugar-filled co-extrusion products. But other than mixing sugar paste, multiple ingredients and products can be used in this newly developed Z-blade mixing system, which is opening the market for other production plants.

We can conclude that Extrufood is the specialist with production systems that occupy less space, consume less energy and need fewer operators than any other system, while achieving the highest product quality and consistency. Extrufood production systems offer state-of-the-art technology with its unique continuous production process and their customised elements such as cooking-, mixing-, and forming extruders, Z-blade mixers, Diemixes, multi-color (co-) extrusion and rotary dies, cooling tunnels, waxing units, sugar sanders and (ultra-sonic) cutting machines.

Extrufood is now more focused than ever on creating products with natural colours and flavours, which are temperature stable. A revolutionary variety of 100% fruit snacks can be made on the Extrufood cooking and forming extruders. The cooking process allows customers to produce a broad spectrum of tasty and healthy products. As today’s world is craving for sweet, Extrufood provides the solution that sweet can also be healthy these days.

Find us in Hall 10.1 stand C059 and have a look at our website Home – Extrugroup

Media contact

Roshini Bains,

Editor, International Confectionery

Tel: +44 (0) 1622 823 922

Email: [email protected]