Rotzinger Group is launching its Robot with an Integrated Buffer and Hygienic Conveyor for dry cleaning. These technologies will be showcased at PACK EXPO Las Vegas, from 11-13 September 2023.

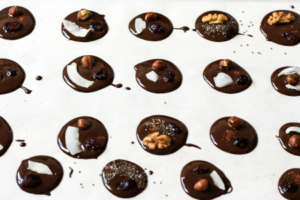

Leveraging decades of expertise in pick and place delta robots, buffering and conveying, the new integrated solution from Rotzinger combines flexibility, compactness and ease of operation to boost uptime and reduce the total cost of ownership. Designed for confectionery and bakery products, the hygienic conveyor is optimised for dry cleaning, ensuring compliance with stringent food safety regulations in US manufacturing.

“We are excited to have the opportunity to connect with our North American customers and prospects in the food sector for the first time since the opening of our US site last year,” said Nicolas Garcia, Vice President & General Manager, Rotzinger Group, North America. “Our Robot with an Integrated Buffer and Hygienic Conveyor have been specifically designed to tackle the escalating concerns regarding labour shortages, space limitations and heightened sanitary requirements in food production. With intuitive controls and a streamlined design, these solutions enhance productivity and optimise operations.”

According to a recent PMMI report, 60% of consumer-packaged goods respondents highlighted a lack of labour as a significant factor driving interest in automated solutions.

To help overcome workforce challenges, the company developed the Robot with an Integrated Buffer, capable of efficiently picking and placing both unpacked and packed products into a number of packaging formats including cartons, cases, thermoforms, flow wrappers and cartoning machines.

With its modular design and flexibility, the integrated solution combines delta robots, buffers and conveyors in one cell, with reduced footprint enabling greater efficiency, productivity and cost-effectiveness. The use of a single controller will enable hassle-free maintenance and straightforward operation, which eliminates the need for complex programming or extensive training.

Equipped with vision-guided high-speed robots, the machine identifies incoming products on the conveyor belt and places them in the feeding process. It utilises optimal counterflow or co-flow techniques, providing versatile solutions to meet diverse production requirements.

According to the Centers for Disease Control and Prevention, around 128,000 individuals in the US suffer from foodborne illnesses each year. To mitigate the risk of contamination and bacterial buildup, it is crucial that food producers maintain clean conveyors along their processing and packaging lines.

Rotzinger has developed a Hygienic Conveyor for dry cleaning, specifically designed to address food safety concerns and adhere to the highest hygienic standards. The conveyor incorporates an intelligent cleaning design, featuring a foldable belt and beveled or rounded horizontal surfaces to prevent the accumulation of dirt particles and crumbs.

The Hygienic Conveyor provides flexibility in size range, accommodating a wide range of requirements. It offers width options ranging from 5.9 to 70 inches and length options from 15 to 1377 inches.

The company combines knowledge and experience in robotics, buffering and conveying from Demaurex, Rotzinger, and Transver, creating efficient systems and new integrated products based on proven solutions.

North American food producers can benefit from local service support, as well as the proprietary Gemini 5.0 hardware and software platform. It offers a user-friendly machine display on the HMI, enabling real-time 3D visualisation. operators can optimise pick and place patterns and zones, maximising efficiency and uptime. The offline simulation mode allows for testing without physical products to reduce waste, setup time and overall cost of ownership.

Stay up-to-date on the latest industry news and exclusives in our magazine.

Never miss a story… Follow us on:

![]() International Confectionery

International Confectionery

![]() @InConfectionery

@InConfectionery

![]() @InConfectionery

@InConfectionery

Media contact

Caitlin Gittins

Editor, International Confectionery

Tel: +44 (0) 1622 823 920

Email: editor@in-confectionery.com