Technical Editor Clay Gordon explores time and temperature and their influence on cooling down chocolate. As he highlights in this article, it can be a highly technical process

In this exclusive feature for International Confectionery Magazine, Technical Editor Clay Gordon highlights a topic that sits between previous topics he’s covered before. In the September issue he wrote about automated materials handling and in the October issue, packaging – in this issue, Clay covers an area that sits in the middle; chocolate cooling.

“The laws of physics that govern the process are the ones that govern the transfer of heat,” he writes in this piece, acknowledging that chocolate cooling is a highly technical process and one that needs to be treated with care. Finding the correct time and temperature can be a balancing act, but works well once perfected.

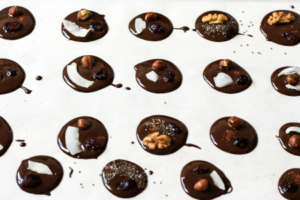

In the September issue of International Confectionery Magazine, I wrote about materials handling in the chocolate-making process, from cleaning cocoa beans through refining to tempering. In the October issue, I wrote about topics related to wrapping, picking, and packing finished bars, confectionery, and baked goods. For this issue I am going to be covering an intermediate stage between the previous two topics – cooling chocolate confectionery – bars and bonbons.

One thing that all three of these topics have in common is the need to move things around the workshop in various stages of completion, from raw ingredients to finished product, from one place to another, in a controlled fashion. While high-speed wrapping, picking, and packing machines rely upon precision timing and placement, with tolerances sometimes measured in fractions of a second and millimetres, cooling tempered chocolate to ensure the longest possible shelf life requires a different kind of precision. It also requires patience.

When chocolate cools down it releases heat, sometimes referred to as the latent heat of crystallisation.

At this point I want to step back and address a point that most readers will be aware of, but is one that I read far too often, even among professionals with experience: Chocolate does not dry out when it transitions from the pourable state to the solid state. There is little to no water in chocolate, so there is nothing to dry out. Instead, as the chocolate cools the cocoa butter crystallises.

Great care is taken to ensure that the chocolate is tempered properly, which involves the formation of the right ratio of the right form (shape) of chocolate crystal. As the chocolate cools down, these “seed” crystals encourage the cocoa butter molecules to settle into the same shape crystal, called Form V (five).

While it is extremely important to generate the right quantity and form of crystal, controlling how the chocolate cools down is equally important. If the environment is too warm, too cold, and/or there is insufficient air circulation to remove the latent heat of crystallisation, the integrity of temper may be compromised. This can manifest itself in one of two ways: either the tempered chocolate is more vulnerable to heat and will bloom more easily or the tempered chocolate will start to over-crystallise more rapidly than otherwise.

Cocoa butter bloom affects the visual appeal of a chocolate…

Stay up-to-date on the latest industry news and exclusives in our magazine.

Never miss a story… Follow us on:

![]() International Confectionery

International Confectionery

![]() @InConfectionery

@InConfectionery

![]() @InConfectionery

@InConfectionery

Media contact

Caitlin Gittins

Editor, International Confectionery

Tel: +44 (0) 1622 823 920

Email: editor@in-confectionery.com