Brusco has seen its innovation in crystallised ginger products pay huge dividends for one long-established master chocolatier in the UK. The powder coated and pre-diced ginger from Brusco has enabled Beech’s Fine Chocolates to revolutionise its enrobing process while still satisfying customer tastes for first-class ginger chocolates with a smooth, luxurious mouthfeel.

Traditionally chocolatiers use stem ginger for enrobing to deliver the soft and smooth texture desired when biting into a chocolate. However, stem ginger creates many sticky and messy manufacturing problems which delay production and add to change over times. The newly-launched powder coated ginger range from Brusco delivers the same soft smooth mouthfeel but without the mess and challenges of production lines clogging up. It also significantly improves yield and reduces waste.

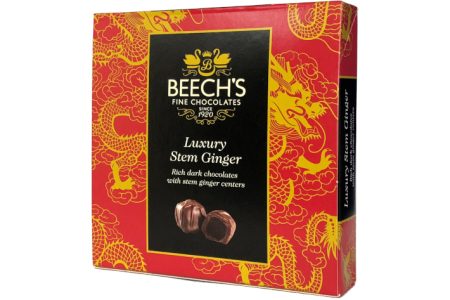

Family-owned Beech’s has been producing high class chocolate products for over 100 years and uses only the best natural ingredients. In preparation for the festive season, the firm recognised that a much slicker system for enrobing its ginger was needed.

The firm had its sights set on cutting out the need to buy ginger in syrup because of the very lengthy and sticky process involved in boiling off the syrup followed by double coating in cocoa powder and chocolate. Thanks to successful product trials with Brusco’s pre-coated and pre-diced crystallised ginger, working with the ingredient became cleaner, easier, and more cost-effective.

With regard to the taste and texture of the finished chocolates, the technology behind Brusco’s manufacturing process means that the product is free flowing, easy to handle and has a smooth surface and texture with no crunchy sugar crystals that are typical of crystallised ginger.

The smooth powder coating brings double satisfaction for confectioners as its delicate nature allows the full flavour of ginger to flourish while unaffecting the sugar content of the chocolates and avoiding a finished product that is too sweet.

Brusco is delighted to offer this new exciting ginger in a variety of sizes and has the flexibility and capability to produce bespoke sizes and shapes to suit all needs. Current sizes range from 3mm all the way up to large 30mm cubes, discs, fingers and other shapes if desired. The company also has the facility to keep stock in line with customer forecasts in order to ensure security of supply.

Beech’s Managing Director, Peter Whiting commented: “Getting the ginger in the right size, with the right amount of sugar coating we liked a lot – especially at the very competitive price Brusco offers. We have been impressed by their punctuality, reliability and communication. In support terms, their customer service has always been excellent as they are easy to work with and good at keeping in touch. We would certainly consider them as a future supplier as we know we can totally rely on them.”

Brusco has also launched a reduced sugar range of crystallised ginger designed to realise a 10% reduction in sugar content and with lower carbohydrate values than the conventional crystallised version. It is ideally suited for inclusion in any product where a strong flavour hit is desired but calories need to be lowered.

The great news for confectioners and food industry innovators is that this low sugar ginger still has a smooth, even surface for enrobing while its full intensity is maintained – perfect if an intense coated ginger is desired, ideal as a snack on its own or to add a flavour punch to other products.

“We are constantly working with our customers to find innovative solutions that reduce production costs. We believe these new ginger products can deliver benefits in many product applications and support the ongoing requirement to reduce sugar levels in products,” commented Brusco’s Managing Director, Andrew Ashby.